Several molding techniques are employed to manufacture PVC household items, depending on the product requirements:

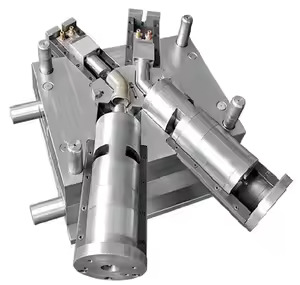

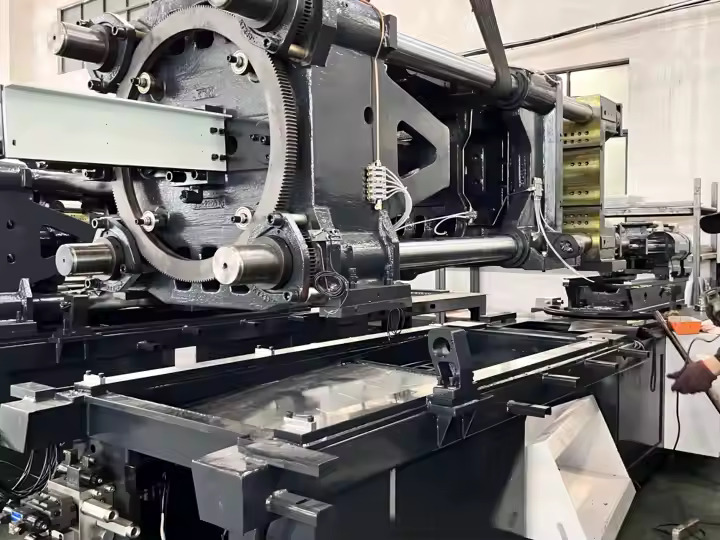

Injection Molding

- Ideal for producing items with intricate designs, such as storage containers, utensil handles, and decorative accessories.

- The process involves injecting molten PVC into a mold cavity, where it solidifies to take the desired shape.

Blow Molding

- Used for hollow items like bottles, jugs, and lightweight containers.

- Involves inflating a parison (molten PVC tube) into a mold to create the hollow form.

Extrusion Molding

- Commonly used for linear items such as curtain rods, pipes, and window frames.

- The process extrudes PVC through a die to achieve continuous shapes.

Compression Molding

- Suitable for larger, simpler items like trays, mats, or panels.

- Involves compressing heated PVC within a mold to form the desired product.

Common Household Items Made from PVC

PVC is used to produce a variety of household items, including:

- Furniture Components: Chair legs, table edges, and armrests benefit from PVC’s strength and flexibility.

- Kitchenware: Items like cutting boards, utensil grips, and food storage containers are durable and easy to clean.

- Storage Solutions: Shelves, bins, and organizers made from PVC are lightweight and long-lasting.

- Bathroom Accessories: Shower curtains, soap dishes, and toothbrush holders are moisture-resistant and hygienic.

- Decorative Products: PVC is used for picture frames, wall panels, and other decorative items, offering customizable designs.

Advantages of PVC Molding for Household Applications

- Lightweight yet Strong: PVC products are easy to handle and durable enough for everyday use.

- Moisture Resistance: Ideal for items used in kitchens, bathrooms, and other humid environments.

- Ease of Maintenance: Non-porous surfaces are easy to clean and resistant to stains.

- Safety and Compliance: PVC formulations for household use are often designed to be non-toxic and meet safety standards.

- Eco-Friendly Options: Recyclable and phthalate-free PVC grades are increasingly used to reduce environmental impact.

Challenges and Solutions in PVC Molding

While PVC molding offers numerous benefits, some challenges exist:

- Heat Sensitivity: Overheating can degrade PVC. Careful temperature control during molding ensures material integrity.

- Environmental Concerns: The production of traditional PVC involves chlorine, raising environmental concerns. Manufacturers are addressing this by adopting bio-based and recyclable PVC formulations.

- Design Limitations: Extremely complex designs may require alternative materials or hybrid molding techniques.