Polyvinyl chloride (PVC) molding is a versatile manufacturing process widely utilized in the packaging industry due to its durability, flexibility, and cost-effectiveness. PVC molding allows for the creation of a variety of packaging solutions, ranging from rigid containers to flexible films, offering significant benefits for industries like food, pharmaceuticals, and consumer goods.

Durability and Protection

PVC packaging provides excellent strength and resistance to environmental factors like moisture, chemicals, and UV exposure. This makes it ideal for protective packaging, ensuring products remain safe during storage and transportation. For example, PVC blister packs are commonly used for medicines and electronics.

Versatility in Design

PVC molding can produce a range of packaging types, including bottles, trays, and shrink wraps. Its moldability allows manufacturers to create intricate designs and custom packaging tailored to specific products, enhancing both functionality and aesthetic appeal. For example, PVC shrink wraps conform tightly to product shapes, offering tamper-proof seals.

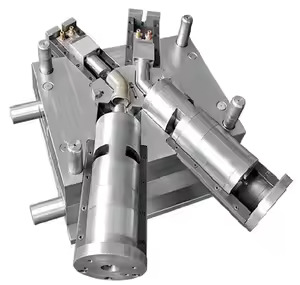

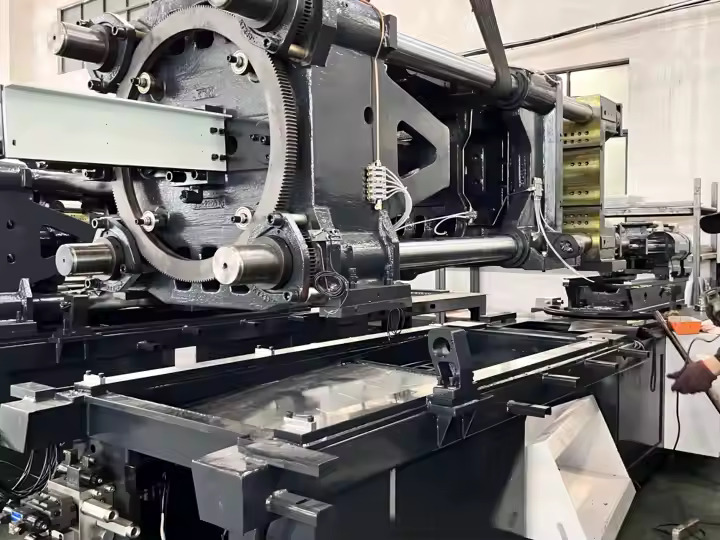

Cost-Effective Production

PVC is a cost-efficient material, making it an attractive option for large-scale packaging solutions. Injection and extrusion molding processes for PVC enable high-speed production of packaging materials with consistent quality, reducing overall manufacturing costs.

Applications in Various Industries

- Food Packaging: PVC is used in clamshell packaging, vacuum-sealed trays, and food-safe films to preserve freshness and prevent contamination.

- Pharmaceuticals: Blister packs made from PVC protect pills and capsules from moisture and light, maintaining their potency.

- Consumer Goods: PVC molding is used for packaging cosmetics, electronics, and toys, combining protection with a polished presentation.

Environmental Considerations

While PVC packaging is highly effective, concerns about its environmental impact have spurred the development of recyclable PVC materials and sustainable alternatives. Innovations in PVC recycling technology are making it possible to reuse materials, reducing waste and the carbon footprint associated with its production.