PVC Molding Innovations in Medical Devices

Polyvinyl Chloride (PVC) continues to be a cornerstone material in medical device manufacturing due to its biocompatibility, flexibility, durability, and cost-effectiveness. With advancements in molding technologies, medical-grade PVC is now being used to create safer, more efficient, and eco-friendly medical products while meeting strict regulatory standards.

Key Innovations in PVC Molding for Medical Devices

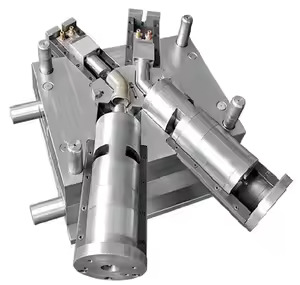

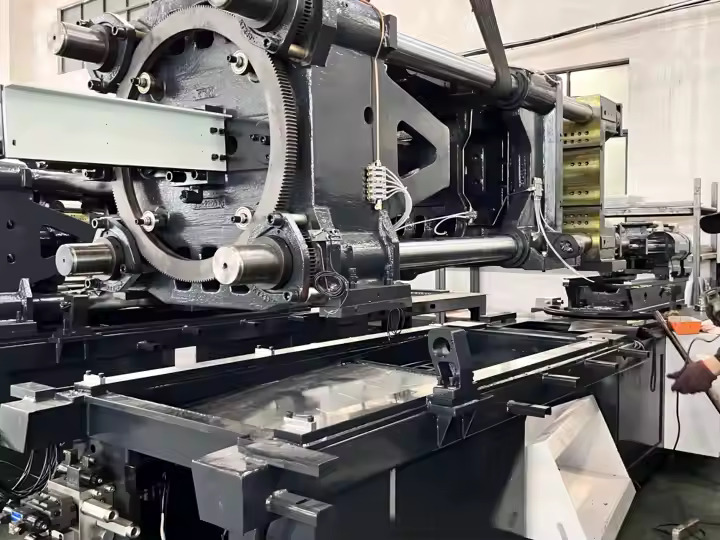

Advanced Injection Molding for Precision & Sterility

- High-precision micro-injection molding allows for the production of small, intricate medical components.

- Cleanroom molding ensures contaminant-free manufacturing for sterile applications.

Flexible & Soft-Touch PVC for Patient Comfort

- Plasticized PVC enhances flexibility, making it ideal for tubing, catheters, and IV bags.

- New soft-touch formulations reduce patient discomfort in medical applications.

PVC Overmolding for Multi-Material Devices

- Combines rigid and soft PVC in a single molding process for ergonomic, durable medical tools.

- Used in syringe grips, diagnostic devices, and surgical instrument handles.

Lead-Free & Phthalate-Free Formulations

- New DEHP-free PVC materials enhance patient safety and compliance with global regulations.

- Non-toxic, biocompatible alternatives improve use in neonatal and sensitive medical applications.

3D Printing & Rapid Prototyping in PVC Molding

- Hybrid additive manufacturing accelerates customized PVC medical device development.

- Enables faster prototyping and regulatory testing for new healthcare solutions.

Common Medical Devices Using PVC Molding

IV Tubing & Blood Bags – Flexible, non-toxic, and sterilizable.

Catheters & Respiratory Masks – Soft, durable, and patient-safe.

Surgical Instruments & Housings – Rigid, impact-resistant, and easy to sterilize.

Gloves & Protective Barriers – Essential for infection control.

Dialysis & Drug Delivery Systems – Ensures safe and controlled fluid transfer.

Future of PVC Molding in Medical Technology

With growing emphasis on biodegradable PVC, antimicrobial surfaces, and AI-driven quality control, the future of PVC medical molding is set to enhance patient safety, sustainability, and innovation. As medical demands evolve, PVC remains a key material in shaping the next generation of healthcare solutions.