Polyvinyl Chloride (PVC) molding is a critical process in industries such as automotive, construction, and consumer goods manufacturing. The handling of PVC molds—often heavy, complex, and hot—requires precision, safety, and consistency. Robotic assistance in this domain offers significant improvements in productivity, safety, and quality.

Challenges in Manual PVC Mold Handling

High Temperature: Molds can reach extremely high temperatures, posing a risk of burns or heat-related injuries.

Heavy Weight: PVC molds, especially in injection molding processes, are often bulky and require multiple operators to lift or move.

Precision Requirements: Misalignment during placement or removal can lead to defects or downtime.

Repetitive Strain: Manual handling leads to repetitive strain injuries and worker fatigue over time.

Contamination Risk: Manual contact may introduce contaminants into the molding environment, affecting product quality.

Benefits of Robotic Assistance

Improved Safety

Robots reduce human exposure to hazardous environments.

Eliminate injuries from lifting or working with hot molds.

Enhanced Precision

Robots provide consistent, repeatable motions with high accuracy in placing, removing, or aligning molds.

Increased Productivity

Continuous operation without fatigue leads to faster cycle times.

Robots can operate in 24/7 production environments.

Better Ergonomics

Removes the physical strain from workers, enhancing workplace ergonomics.

Contamination Control

Automated handling reduces human contact, improving cleanliness and product consistency.

Types of Robots Used

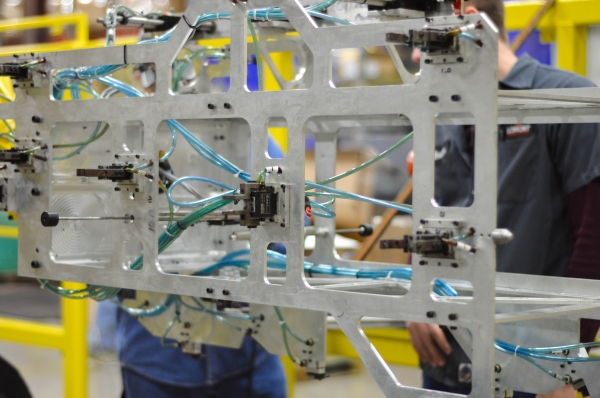

Articulated Robotic Arms

Flexible for complex movements.

Common in injection molding and assembly lines.

SCARA Robots

Ideal for horizontal movements and precise placements.

Cartesian Robots

Offer high-speed, linear movement; suitable for pick-and-place operations.

Collaborative Robots (Cobots)

Work safely alongside humans; useful in hybrid manual-automated systems.

Common Applications in PVC Mold Handling

Mold Loading and Unloading

Robots lift and place molds into injection or blow molding machines.

Part Removal

After molding, robots extract finished PVC parts without damaging them.

Tool Changing

Automated tool changers assist in switching molds or end-effectors.

Quality Inspection

Vision-equipped robots perform defect detection and dimensional checks.

Integration Considerations

End-Effector Design

Must be customized to handle the specific mold geometry and weight.

Environmental Factors

Robots must be heat-resistant or operate in temperature-controlled zones.

Control Systems

Integration with PLCs and HMI systems for real-time monitoring and coordination.

Safety Mechanisms

Light curtains, safety zones, and emergency stops are essential.

Case Studies and Results

Automotive Supplier: A manufacturer reduced cycle time by 30% and eliminated workplace injuries after deploying robotic mold handlers.

Medical Device Company: Improved product cleanliness and reduced defect rates by using robotic arms in cleanroom PVC molding processes.

Conclusion

Robotic assistance in PVC mold handling not only enhances operational efficiency and safety but also sets a foundation for smarter, Industry 4.0-enabled manufacturing processes. As robotic technologies evolve, their adoption in mold handling will become even more critical for maintaining competitiveness and compliance in manufacturing sectors.