Computer-Aided Design (CAD) plays a pivotal role in the design and development of injection molds, enhancing efficiency, precision, and innovation in the manufacturing process. CAD tools streamline the entire mold design workflow, enabling manufacturers to meet the demands of complex geometries and tighter tolerances in modern production.

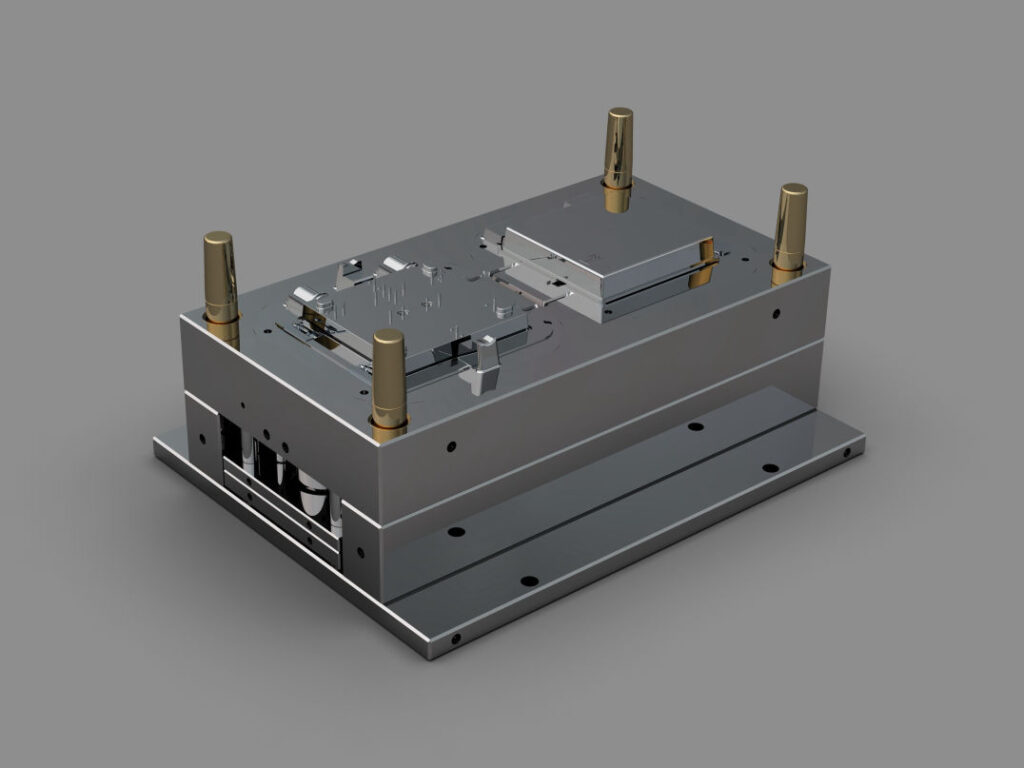

Precision and Complexity in Mold Geometry

CAD systems enable designers to create highly intricate and precise mold geometries. Using 3D modeling capabilities, engineers can visualize the mold and ensure every detail meets the exact specifications required for the part. This precision is critical for maintaining consistency in high-volume production.

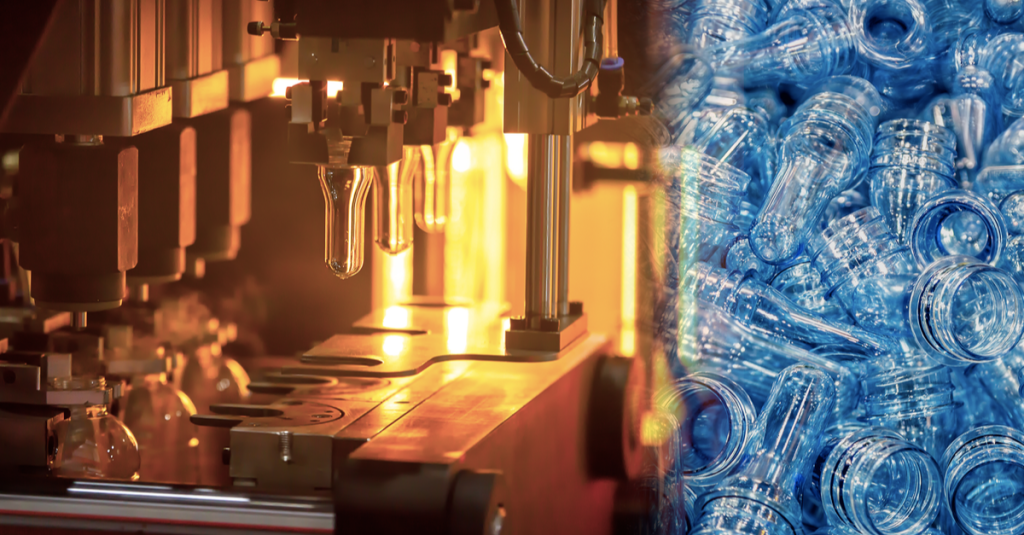

Simulation and Analysis

CAD software is integrated with simulation tools that predict the behavior of materials during the injection molding process. These simulations help engineers analyze material flow, cooling patterns, and potential defects like warping or shrinkage. By addressing these issues early in the design phase, CAD reduces the need for costly and time-consuming physical prototyping.

Iterative Design and Optimization

With parametric modeling in CAD, designers can quickly modify mold dimensions or features without starting from scratch. This iterative capability allows for rapid optimization, ensuring molds meet functional and aesthetic requirements while minimizing waste.

Collaboration and Integration

Modern CAD platforms often include cloud-based features, enabling real-time collaboration among team members across different locations. Designers, engineers, and manufacturers can work on the same model simultaneously, ensuring seamless communication and reducing errors in the design-to-production transition.

Cost and Time Efficiency

By enabling virtual prototyping and simulation, CAD eliminates much of the trial-and-error traditionally associated with mold design. This reduces the number of physical prototypes needed, saving both time and materials, and accelerating the time-to-market for products.

Design for Manufacturability

CAD software ensures that mold designs are optimized for manufacturing. By simulating tool paths and machining processes, it identifies potential issues that could arise during mold production. This integration with CAM (Computer-Aided Manufacturing) systems ensures that molds are ready for CNC machining without manual rework.

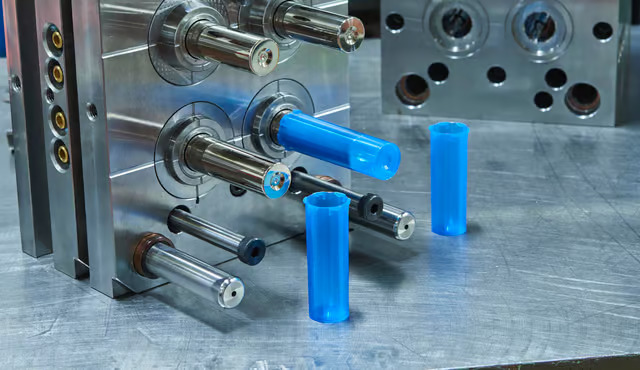

Accommodating Material Properties

CAD tools incorporate libraries of material properties, allowing engineers to design molds tailored to specific materials such as thermoplastics, elastomers, or composites. This ensures that molds perform effectively with the chosen materials, maintaining product quality.