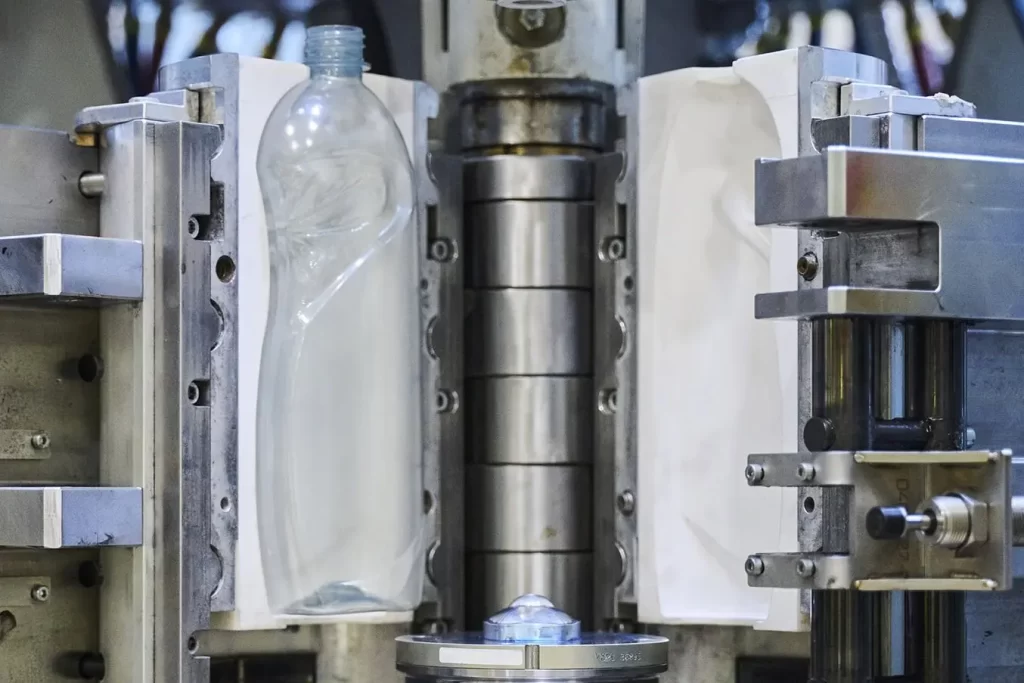

Blow moulding is a manufacturing process used to produce hollow plastic parts, such as bottles, containers, and tanks. One of the most critical factors influencing the efficiency, cost-effectiveness, and quality of this process is mould design. An optimally designed mould not only ensures the desired shape and strength of the final product but also significantly enhances production speed, material utilization, and product consistency.

1. Precision and Product Quality

Mould design determines the final geometry of the blow-moulded part. A well-designed mould:

Ensures dimensional accuracy and wall thickness uniformity.

Reduces the occurrence of defects such as warping, flash, or poor sealing.

Enables consistent reproduction of complex shapes and details.

2. Cycle Time Optimization

Efficient mould design contributes to faster cycle times by:

Incorporating rapid cooling channels to reduce cooling time.

Allowing quick release mechanisms for faster part ejection.

Minimizing material reheating or uneven shrinkage that could delay demoulding.

3. Material Efficiency

Good mould design minimizes material waste by:

Allowing precise control over wall thickness.

Reducing excess flash or trim.

Enabling better parison placement and stretch during the process.

4. Energy Efficiency

A thermally optimized mould:

Enhances energy savings by maintaining consistent temperatures.

Reduces energy spent on excessive cooling or reheating.

Supports sustainable production goals by lowering the carbon footprint.

5. Ease of Maintenance and Durability

A robust mould design ensures:

Longer mould life with wear-resistant components.

Easier access for cleaning, repair, and component replacement.

Reduced downtime due to maintenance.

6. Compatibility with Automation

Modern blow moulding operations increasingly use automation for high-volume production. A well-designed mould:

Facilitates robotic handling of parts.

Integrates sensors for real-time quality control.

Allows for quick mould changes in multi-cavity systems.

7. Product Versatility

Flexible mould designs (e.g., modular moulds) enable:

Quick adaptation to different product sizes or shapes.

Rapid prototyping and testing with minimal retooling.

Broader product range from a single machine setup.

Conclusion

The efficiency of the blow moulding process is heavily influenced by the design of the mould. From reducing cycle time and material waste to improving product quality and process automation, a well-engineered mould plays a pivotal role. Investing in high-quality mould design not only enhances immediate production metrics but also provides long-term benefits in terms of reliability, scalability, and cost-effectiveness.