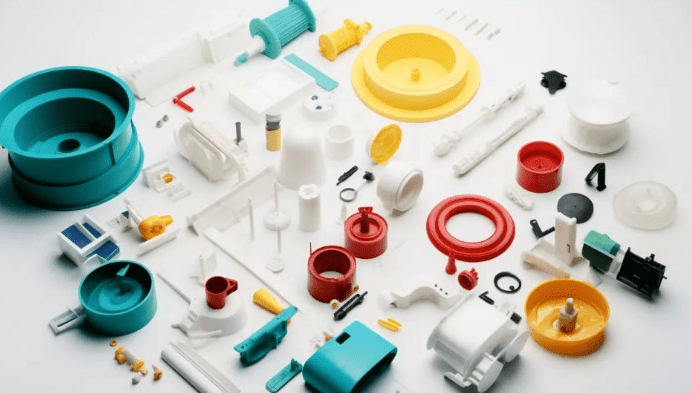

Injection molding is a widely used manufacturing process for producing plastic parts in large volumes. Traditionally, this process relies on petroleum-based polymers which pose significant environmental challenges, including carbon emissions, non-biodegradability, and pollution. As environmental regulations tighten and consumer demand for green products grows, sustainable plastics have emerged as a key innovation in injection molding applications.

What Are Sustainable Plastics?

Sustainable plastics are materials that are designed to minimize environmental impact throughout their lifecycle. These plastics typically fall into three main categories:

Bioplastics: Derived from renewable biomass sources such as corn starch, sugarcane, or cellulose.

Recycled Plastics: Produced by reprocessing used plastic materials.

Biodegradable Plastics: Capable of breaking down naturally in the environment through microbial action.

Types of Sustainable Plastics for Injection Molding

Polylactic Acid (PLA)

Source: Corn starch or sugarcane

Advantages: Biodegradable, compostable, good dimensional stability

Applications: Packaging, consumer products, disposable items

Limitations: Lower heat resistance and mechanical strength compared to traditional plastics

Polyhydroxyalkanoates (PHA)

Source: Produced by bacterial fermentation of organic materials

Advantages: Fully biodegradable, good mechanical properties

Applications: Medical devices, packaging, agricultural films

Limitations: Higher cost, limited commercial availability

Recycled Polyethylene Terephthalate (rPET)

Source: Recycled PET bottles and containers

Advantages: Reduces plastic waste, cost-effective

Applications: Automotive components, packaging, textiles

Limitations: Quality degradation over multiple recycling cycles

Recycled Polypropylene (rPP) and Polyethylene (rPE)

Source: Post-consumer or post-industrial waste

Advantages: Versatile, good for non-critical applications

Applications: Storage bins, piping, automotive parts

Limitations: Inconsistent material properties, contamination issues

Starch-Based Plastics

Source: Corn, potato, or tapioca starch

Advantages: Compostable, renewable source

Applications: Packaging, disposable cutlery

Limitations: Limited durability and moisture resistance

Advantages of Using Sustainable Plastics in Injection Molding

Reduced Carbon Footprint: Lower greenhouse gas emissions compared to petroleum-based plastics.

Waste Minimization: Use of recycled or biodegradable materials helps reduce landfill and ocean waste.

Compliance with Regulations: Helps companies meet global environmental standards (e.g., EU Green Deal, U.S. EPA guidelines).

Consumer Appeal: Aligns with consumer preference for eco-friendly products.

Challenges and Considerations

Material Performance: Sustainable plastics may have lower thermal or mechanical properties than conventional polymers.

Cost: Bioplastics and high-quality recycled materials can be more expensive to produce.

Processing Requirements: Some sustainable materials require adjustments in mold design, temperature control, or cycle time.

Availability and Supply Chain: Limited availability and inconsistent quality of some bioplastics and recycled resins.

Future Outlook

With ongoing research and innovation, sustainable plastics are becoming more competitive in terms of cost and performance. Advances in chemical recycling, bio-based polymer synthesis, and additive technology are paving the way for broader adoption of eco-friendly materials in injection molding.

Government incentives, extended producer responsibility (EPR) programs, and sustainability reporting requirements are also pushing industries to transition toward greener alternatives.

Conclusion

Sustainable plastics offer a promising path forward for making injection molding processes more environmentally responsible. While challenges remain, the combination of regulatory pressure, technological advances, and consumer demand is accelerating the shift toward sustainable materials. Adopting these alternatives not only benefits the planet but also strengthens brand reputation and positions companies as leaders in responsible manufacturing.