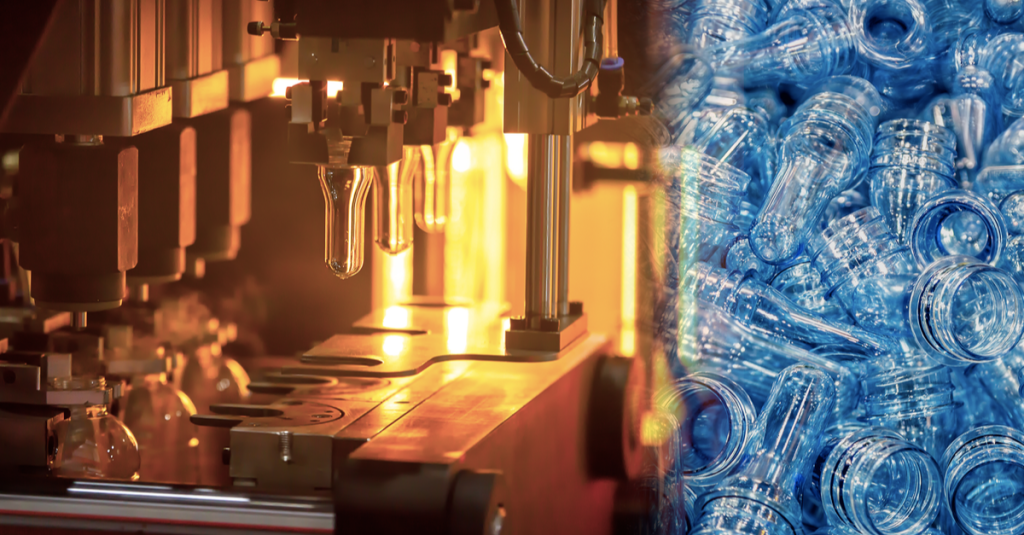

Automation has become a cornerstone of modern injection molding, revolutionizing the industry by enhancing efficiency, precision, and flexibility. Automated systems streamline the manufacturing process, reducing cycle times, minimizing waste, and ensuring consistent product quality. Robots and advanced machinery handle repetitive tasks such as material loading, part removal, and post-processing, accelerating production while lowering energy consumption and operational costs. This efficiency is critical in competitive industries like automotive, healthcare, and electronics, where precision and consistency are paramount.

One of the key advantages of automation is its ability to deliver exceptional accuracy. Automated machines operate within precise parameters, reducing variations between parts and ensuring uniformity across production runs. This level of reliability is vital in applications where even minor deviations can compromise product functionality. Furthermore, automation minimizes human intervention, reducing the risk of errors and enabling manufacturers to allocate their workforce to higher-value tasks such as quality control and innovation.

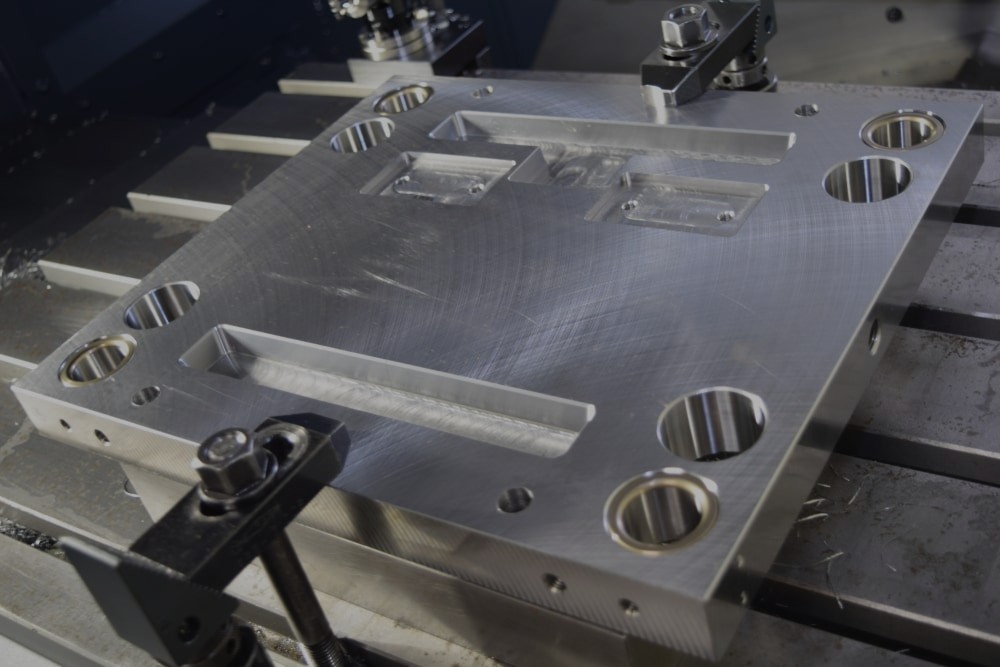

Automation also enhances adaptability and customization in injection molding. Modern systems can be quickly reprogrammed to produce different parts, allowing manufacturers to respond to changing market demands and support smaller production runs. This flexibility is further bolstered by the integration of smart technologies like IoT sensors, machine learning, and real-time data analytics. These innovations enable predictive maintenance, optimize machine performance, and ensure efficient resource utilization, reducing downtime and operational disruptions.

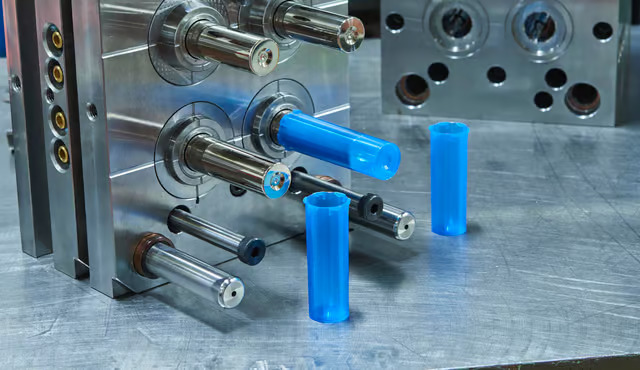

Sustainability is another significant benefit of automation in injection molding. By optimizing material usage and reducing scrap rates, automated systems support eco-friendly manufacturing practices. Energy-efficient machines and the effective incorporation of recycled materials further align with sustainability goals, helping businesses meet environmental standards while maintaining profitability.