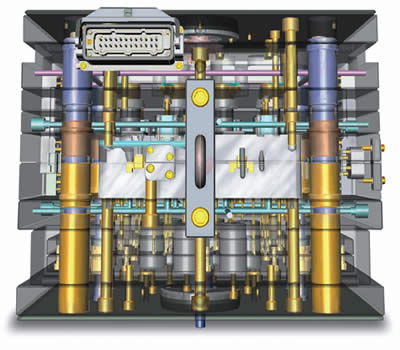

Mould design plays a critical role in determining the final appearance and perceived quality of a product. While functionality and performance are essential aspects of any product, aesthetics greatly influence consumer appeal, brand perception, and market success. The design and precision of the mould directly affect surface finish, dimensional accuracy, texture, and consistency — all of which contribute to the visual and tactile experience of the end product.

1. Surface Finish and Texture

One of the most immediate aesthetic aspects affected by mould design is the surface finish. The quality of the mould surface — whether it is polished, textured, or matte — transfers directly to the product. High-quality moulds with mirror-polished surfaces result in smooth, glossy products, while textured moulds can create sophisticated patterns or tactile features that enhance both appearance and grip.

2. Precision and Dimensional Accuracy

Aesthetic appeal is often linked to the precision of the product’s shape and form. Any mismatch, warping, or flash caused by poorly aligned or worn moulds can result in noticeable defects, undermining the visual quality of the product. A well-designed mould ensures tight tolerances, sharp edges, and clean lines, all of which contribute to a premium look and feel.

3. Consistency and Repeatability

In mass production, maintaining consistency across units is vital for brand reputation and customer satisfaction. Mould design must accommodate repeatable production with minimal variation. Even minor inconsistencies in shape or finish can disrupt a product line’s aesthetic harmony and lead to rejections or returns.

4. Material Flow and Gate Placement

The flow of molten material within the mould affects how the product is filled, cooled, and formed. Poor material flow can result in weld lines, sink marks, or air traps, which are not only functional concerns but also cosmetic issues. Strategic gate placement and balanced flow paths ensure that visual defects are minimized, and surface aesthetics remain intact.

5. Parting Line Considerations

The parting line — where two halves of the mould meet — is often visible on the final product. Mould designers carefully consider the placement of the parting line to ensure it aligns with less visible or less critical areas of the product. Misplaced or prominent parting lines can detract from the aesthetic value, especially in consumer-facing products.

6. Integration with Branding Elements

Moulds can also be designed to include logos, textures, or decorative features directly into the product. Embossing or engraving branding elements into the mould ensures permanence and eliminates the need for secondary operations, all while enhancing the product’s aesthetic and brand identity.

7. Influence on Post-Processing

The quality of the mould directly affects the need for and effectiveness of post-processing steps like painting, plating, or assembly. A well-finished mould can reduce or even eliminate the need for surface preparation, preserving both the intended design and the cost-effectiveness of production.

Conclusion

Mould design is far more than a technical step in manufacturing — it is a foundational contributor to product aesthetics. From the choice of surface finish to the integration of brand elements, every decision in the mould design process influences how a product looks and feels. For manufacturers seeking to deliver high-quality, visually appealing products, investing in thoughtful and precise mould design is essential.