Thermoforming is a widely used manufacturing process in the production of disposable housewares such as plates, bowls, cups, trays, and food containers. It involves heating a plastic sheet to a pliable forming temperature, shaping it to a mold (die), and then trimming it to create the final product. Central to the success of this process are thermoforming dies, which directly determine the quality, precision, and efficiency of the final product.

Role of Dies in Thermoforming

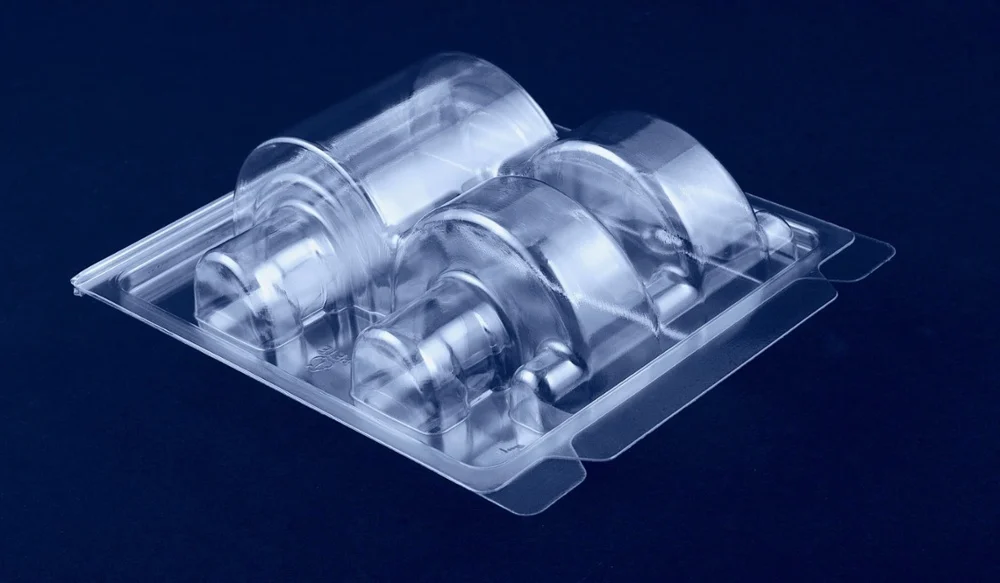

Thermoforming dies (also known as molds) are precision-engineered tools used to shape heated plastic sheets into desired forms. In the context of disposable housewares, these dies must produce consistent, cost-effective, and food-safe products at high production volumes.

Types of Dies Used

Depending on the type of forming process and desired product characteristics, several types of dies are used:

Male Dies (Plug Assist Molds)

A male die protrudes into the plastic sheet to form the shape.

Used for deep-draw applications such as cups and containers.

Often combined with a plug assist to control wall thickness.

Female Dies (Cavity Molds)

The plastic sheet is drawn into a cavity mold.

Suitable for shallow items like trays and plates.

Matched Mold Dies

Involve both male and female components.

Offer high precision and uniform wall thickness.

Vacuum and Pressure Forming Dies

Equipped with vacuum channels or pressure systems to aid in forming.

Provide finer details and smoother surfaces.

Materials Used for Dies

Thermoforming dies for disposable housewares are typically made from:

Aluminum (CNC-Machined or Cast)

Lightweight, durable, and provides excellent thermal conductivity. Ideal for high-volume production.Epoxy or Urethane Tooling Board

Cost-effective and fast to produce. Common for prototyping and short runs.Steel

Used where extreme durability is required, though less common for disposable items due to higher cost.

Design Considerations

When designing thermoforming dies for disposable housewares, several factors must be taken into account:

Draft Angles

To allow easy part removal from the mold.Ventilation

Small vents allow air to escape, ensuring proper plastic-to-mold contact.Heating Efficiency

Die design should support even heating for uniform forming.Surface Finish

Textured or smooth finishes to match product requirements.Cycle Time Optimization

Efficient cooling channels and mold design reduce cycle times, increasing productivity.

Applications in Disposable Housewares

Thermoforming dies are crucial in producing:

Disposable Plates and Bowls

Uniform depth and strength, often using female cavity molds.Cups and Lids

Deep-draw designs made using male plug-assist molds.Food Trays and Containers

Multi-cavity molds for high-volume production.Cutlery and Other Accessories

Precision dies used for shaping finer details.

Advantages of Using Thermoforming Dies

High Production Speed

Ideal for mass production of disposable items.Cost-Effective Tooling

Compared to injection molding, thermoforming dies are cheaper and faster to manufacture.Flexibility

Easy to customize for different product shapes and sizes.Material Efficiency

Thin plastic sheets reduce material use and waste.

Conclusion

Thermoforming dies play a pivotal role in the cost-effective and efficient production of disposable housewares. With advancements in die design, materials, and manufacturing technologies, manufacturers can achieve high precision, shorter cycle times, and greater flexibility in product development. As the demand for sustainable and hygienic disposable products grows, the importance of optimized thermoforming dies will only continue to increase.