1. Introduction

Transfer dies are a type of progressive tooling system used in high-volume metal forming processes. Unlike traditional progressive dies where the part remains attached to the strip, transfer dies work in conjunction with a transfer mechanism that moves individual parts from one station to the next. This system enables the creation of more complex part geometries and accommodates deep-drawn or large components.

2. Function of Transfer Dies

The primary function of transfer dies is to perform a sequence of metal forming operations on a workpiece as it moves through multiple die stations. These operations can include:

Blanking: Cutting flat shapes from sheet metal.

Piercing: Creating holes or shapes within the blank.

Forming: Bending or shaping the metal without removing material.

Drawing: Pulling the material into a die to create deeper shapes or cavities.

Trimming: Removing excess material or flash from the formed part.

Coining and embossing: Adding detailed features, logos, or functional surfaces.

Unlike progressive dies, transfer dies separate the part from the strip early in the process. A transfer mechanism then moves the part between stations, enabling the handling of larger, more complex parts and more extensive operations.

3. Structure of Transfer Dies

Transfer dies are typically made up of the following key components:

A. Die Stations

Each station performs a specific operation. The number of stations varies depending on the complexity of the part. The part is transferred from station to station by mechanical arms or robotic systems.

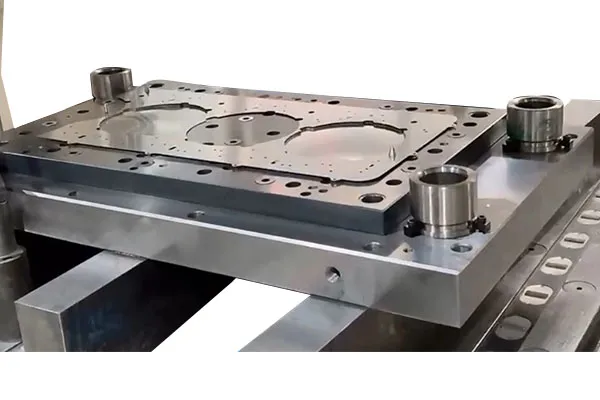

B. Upper and Lower Die Sets

These provide the structural support for the forming tools and ensure precise alignment during the stamping operation. They house:

Punches (attached to the upper die)

Dies/cavities (in the lower die)

C. Transfer Mechanism

A critical part of the system, the transfer mechanism automatically moves the part from one station to the next. It can be:

Mechanical (cam-driven)

Servo-driven

Robotic arm-based

The mechanism must be precisely timed with the press stroke to ensure smooth and accurate part handling.

D. Guide and Alignment Systems

Precision guide pins, bushings, and alignment blocks ensure proper alignment between the upper and lower dies and consistent part placement during transfer.

E. Support Components

These include:

Die shoes and bolster plates

Stripper plates to remove parts from punches

Springs, gas cylinders, or nitrogen cylinders for force modulation

Sensors for monitoring part presence, alignment, and die protection

4. Advantages of Transfer Dies

Capable of handling large or complex parts

Allows for deep drawing and multiple forming operations

Greater flexibility in part design

Efficient for medium to high-volume production

Enables tight tolerance control and consistent quality

5. Applications of Transfer Dies

Transfer dies are commonly used in:

Automotive manufacturing (body panels, structural components)

Appliance production (washer/dryer panels, internal structures)

Aerospace components

Heavy equipment parts

6. Summary

Transfer dies are a versatile and powerful tooling solution designed for the high-efficiency production of complex metal parts. Their structure, combined with an automated transfer system, allows for flexibility in part design and consistency in manufacturing. By separating the part early in the process and moving it independently between stations, transfer dies overcome many of the limitations of conventional progressive dies.