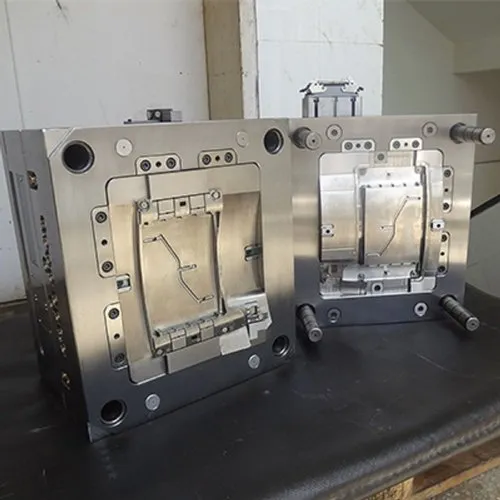

Injection molding is a widely used manufacturing process in which molten material (often plastic) is injected into a mold to create a wide range of products. The design of the mold plays a crucial role in the production process, affecting factors such as efficiency, cost, and the type of products that can be produced. Two common types of molds used in injection molding are single cavity molds and multi-cavity molds. Here’s an overview of both:

1. Single Cavity Mold

A single cavity mold is a type of mold that has one cavity to produce a single part per cycle. This mold is typically used when only one product is required to be manufactured at a time.

Advantages of Single Cavity Molds:

- Lower initial costs: Single cavity molds generally require a smaller investment upfront since they are simpler to design and manufacture compared to multi-cavity molds.

- Lower complexity: The mold design and process are less complex, making it easier to maintain and troubleshoot.

- Easier quality control: With only one part being made at a time, it’s easier to ensure consistent quality and make adjustments if needed.

- Better for low-volume production: This type of mold is ideal for producing smaller quantities of products where the cost of setting up a more complex mold wouldn’t be justified.

Disadvantages of Single Cavity Molds:

- Lower production efficiency: Since only one part is produced per cycle, the overall output rate is slower, making it less efficient for high-volume production.

- Higher per-part cost: While the mold itself is cheaper to produce, the per-unit cost may be higher compared to multi-cavity molds when producing large quantities.

Applications of Single Cavity Molds:

- Custom parts or low-volume runs

- Prototypes

- Products that require very high precision or intricate features, where production speed is less important

2. Multi-Cavity Mold

A multi-cavity mold contains multiple cavities within the same mold tool, allowing the simultaneous production of several parts in each injection cycle. These molds are designed to produce identical parts in large quantities, and the number of cavities can vary depending on the specific needs of the production process.

Advantages of Multi-Cavity Molds:

- Higher production efficiency: Multi-cavity molds are ideal for high-volume production since they can produce several parts per cycle. This increases the overall output and reduces production time.

- Lower per-part cost: With more parts being produced at once, the cost per part decreases, making it more cost-effective for large-scale production runs.

- Better use of equipment: By producing multiple parts simultaneously, multi-cavity molds maximize the usage of injection molding machines, leading to higher productivity.

- Consistency: Multi-cavity molds ensure that parts are produced under identical conditions, improving uniformity and consistency across large batches.

Disadvantages of Multi-Cavity Molds:

- Higher initial costs: Multi-cavity molds are more expensive to design and build, as they require more complex mold tooling and greater precision.

- Increased complexity: The mold design and manufacturing process are more intricate, and any issues (such as wear or defects) may affect multiple parts simultaneously.

- Maintenance challenges: Since multiple cavities are working together, maintaining consistent performance across all cavities can be difficult. Wear on one cavity can affect the entire mold.

- Not ideal for prototypes or small batches: The high initial investment makes multi-cavity molds unsuitable for low-volume or prototype production.

Applications of Multi-Cavity Molds:

- Mass production of consumer goods (e.g., bottle caps, packaging)

- Automotive components

- Parts with high-volume demand in industries like electronics, toys, medical devices, and consumer products

Key Differences Between Single Cavity and Multi-Cavity Molds

| Aspect | Single Cavity Mold | Multi-Cavity Mold |

|---|---|---|

| Production Rate | One part per cycle | Multiple parts per cycle |

| Cost | Lower initial cost, higher per-part cost | Higher initial cost, lower per-part cost |

| Efficiency | Lower production efficiency | High production efficiency |

| Complexity | Simple design and maintenance | Complex design and maintenance |

| Ideal Use | Low-volume production, prototypes, high precision parts | High-volume production runs |