Mould design is a critical phase in the manufacturing process of plastic, metal, and composite components. Traditionally, mould design involved a significant amount of trial and error, leading to longer development cycles, higher costs, and increased material waste. However, with the advent of advanced simulation software, the landscape of mould design has significantly transformed.

1. Introduction to Simulation in Mould Design

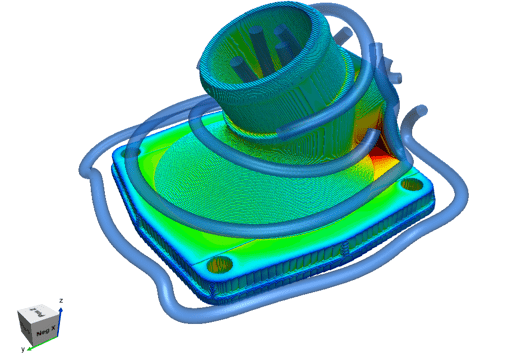

Simulation software enables engineers and designers to create virtual models of moulds and simulate the injection moulding or casting processes. These simulations provide insights into material flow, heat transfer, cooling times, shrinkage, warpage, and potential defects, long before physical moulds are produced.

2. Key Benefits of Simulation Software

Design Validation Before Manufacturing: Engineers can test multiple design iterations virtually, identifying and correcting problems early in the design phase.

Reduced Time to Market: Virtual simulations reduce the number of physical prototypes required, shortening the development cycle.

Cost Savings: Minimizing trial-and-error in physical moulds reduces tooling costs, scrap rates, and rework.

Enhanced Product Quality: Simulation helps in predicting and preventing common defects like air traps, weld lines, short shots, and warpage.

Optimization of Process Parameters: The software can help optimize injection pressure, temperature, cooling time, and other parameters to ensure efficient and stable production.

3. Common Types of Simulation in Mould Design

Mould Flow Analysis (MFA): Simulates the flow of molten material into the mould to identify issues like incomplete filling, weld lines, and air traps.

Cooling Analysis: Examines the cooling channels and evaluates temperature distribution to reduce cycle time and warpage.

Warp and Shrinkage Prediction: Predicts dimensional changes due to uneven cooling and material behavior.

Structural Analysis: Evaluates the strength and durability of the mould tool under pressure and thermal loads.

Thermal Analysis: Helps in identifying hotspots and ensuring uniform temperature distribution.

4. Popular Simulation Software in Mould Design

Autodesk Moldflow

Simcon CADMOULD

ANSYS Polyflow

Moldex3D

SolidWorks Plastics

SigmaSoft Virtual Molding

These tools provide a comprehensive suite of simulations that help engineers make informed decisions throughout the mould design and production planning stages.

5. Applications in Industry

Simulation software is widely used across industries such as:

Automotive: For designing lightweight, high-performance plastic parts.

Consumer Goods: To ensure high aesthetic and dimensional quality.

Medical Devices: Where precision and compliance are critical.

Aerospace: For complex geometries and high-strength components.

6. Challenges and Considerations

While simulation software offers immense benefits, it requires:

Skilled personnel to interpret simulation results accurately.

High-quality material data and process parameters for accurate predictions.

Integration with CAD/CAE systems for streamlined workflows.

7. Conclusion

The use of simulation software in mould design has become an indispensable part of modern manufacturing. It enhances the design accuracy, improves product quality, and reduces time and cost associated with mould development. As technology continues to evolve, simulation tools are expected to become even more powerful and accessible, further revolutionizing the mould design process.