Injection molding is a widely used manufacturing process for producing plastic parts in high volumes. However, like many industrial processes, it can generate significant waste if not properly managed. Adopting zero-waste strategies in injection molding not only reduces environmental impact but also improves operational efficiency and cost-effectiveness. Below are key zero-waste strategies commonly implemented in this industry:

1. Optimized Design for Manufacturability

Designing parts with waste reduction in mind is the first step toward achieving zero waste. This includes:

Minimizing part complexity to reduce material use and cycle time.

Uniform wall thicknesses to avoid sink marks and reduce scrap rates.

Designing for recyclability, making it easier to reuse or recycle parts at the end of their life cycle.

2. Regrinding and Reuse of Scrap

Regrinding involves collecting sprues, runners, and rejected parts, grinding them, and mixing the regrind with virgin material for reuse.

Many engineering plastics tolerate up to 20-30% regrind without significant property loss.

Closed-loop systems ensure that waste stays in-house and is repurposed for future production.

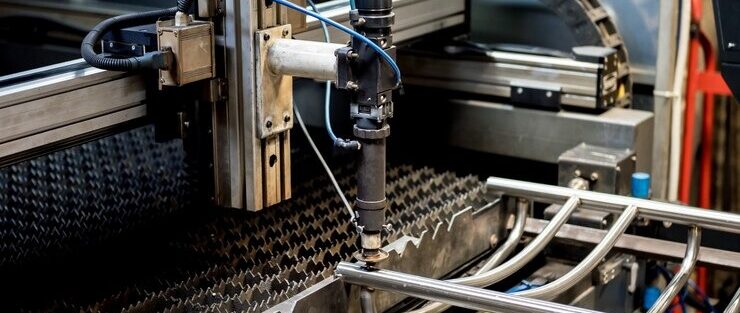

3. Hot Runner Systems

Hot runner systems eliminate the need for cold runners, which are a common source of waste in conventional molds.

These systems deliver molten plastic directly to the cavity, reducing or eliminating scrap from runners.

Though more expensive upfront, hot runners contribute significantly to zero-waste goals and reduce material costs over time.

4. Material Selection and Management

Choosing the right material is crucial:

Use biodegradable or recyclable plastics when feasible.

Implement strict inventory control to prevent material expiration or degradation.

Proper drying and handling procedures reduce material contamination and defects.

5. Process Optimization

Advanced process controls and monitoring systems help reduce cycle time, reject rates, and energy consumption.

Utilize Scientific Molding practices to maintain process stability.

Regular preventive maintenance avoids defects caused by worn molds or equipment issues.

Real-time monitoring detects deviations early, minimizing scrap generation.

6. Lean Manufacturing Principles

Lean principles like Kaizen, 5S, and Value Stream Mapping help identify and eliminate waste throughout the production line.

Improve workflow and layout to reduce handling waste.

Continuous improvement efforts foster a culture of waste minimization.

7. Energy Efficiency

Energy waste indirectly contributes to environmental waste. Strategies include:

Using energy-efficient machines and drives.

Recovering waste heat for other plant processes.

Implementing machine idle-time reduction techniques.

8. Training and Culture

Employee awareness and involvement are essential for a zero-waste approach.

Conduct regular training sessions on waste reduction practices.

Encourage feedback and suggestions from staff to improve sustainability efforts.

9. Recycling Partnerships

When internal reuse isn’t possible, partnering with external recyclers ensures materials are processed responsibly.

Establish agreements to recycle off-spec parts and used packaging.

Explore take-back programs for end-of-life products.

10. Digital Twin and Simulation

Advanced tools such as digital twins and mold flow simulations help predict and avoid potential issues before production begins.

Simulate part design and mold behavior to minimize trial-and-error waste.

Optimize gate locations, cooling channels, and flow paths to improve part quality.

Conclusion

Zero-waste injection molding is a multifaceted approach that requires strategic planning, advanced technology, and a culture committed to sustainability. By integrating design optimization, material reuse, process control, and employee engagement, manufacturers can significantly reduce waste, lower costs, and contribute to a more sustainable future.